Practical experience - Direct or indirect visual inspection

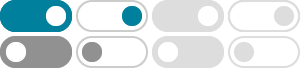

Direct or indirect Visual Inspection - What is the difference? Visual testing, often abbreviated as VT, is an optical or visual non-destructive material testing. It is used for quality assurance or in maintenance and repair.

Visual Testing (VT) Method for NDT Inspections - asnt.org

Visual testing is an NDT method that involves the direct observation of a component to detect surface discontinuities. It is the simplest and most fundamental form of NDT, often serving as a preliminary step before applying more complex methods.

4.1 Direct inspection When direct inspection is employed it shall be performed when access is sufficient to place the eye within 24” of the surface to be examined and at an angle not less than 30° to the surface to be examined.

Visual Inspection: An In-Depth Guide [New for 2025]

Direct visual inspection involves an inspector physically observing the object with their eyes or using basic tools to enhance their view. The simplicity and immediacy of direct visual inspection make it a cost-effective and essential method for initial evaluations and routine checks.

Quality Inspections: A Guide to Visual Inspection Techniques

2023年4月19日 · Direct visual inspection is a simple and straightforward technique for inspecting products and checking whether the product’s dimensions meet the required specifications. The inspector visually examines the products using precision measuring tools such as calipers or …

Introduction To Visual Testing - World Of NDT

2020年1月21日 · Visual testing is the observation of a test object, either directly with the eyes or indirectly using optical instruments, by an inspector to evaluate the presence of surface anomalies and the object’s conformance to specification.

Follow written instructions and process the inspection test pieces, record and report defects from know datum markers, carry out pre test calibration checks, post test procedures.

Visual Inspection: Techniques, Innovations and Applications

2024年11月27日 · Visual inspection tests are classified into two main types: direct and indirect, each serving distinct purposes based on accessibility and inspection criteria. Direct visual inspection Involves using the naked eye or basic tools like magnifiers to examine readily accessible surfaces.

Types of Visual Inspection in NDT: Methods & Techniques

2025年1月10日 · 1. Direct Visual Inspection. This method involves the direct visual examination of an object's surface using the naked eye or basic inspection tools. This method can detect visible surface defects, weld discontinuities, corrosion, and other anomalies that can be identified by visual observation.

What is a Visual Inspection?

2024年8月15日 · Direct visual inspection is the simplest and most common type. It involves an employee looking directly at the object or area that needs to be checked. This can be done with the naked eye or with the help of simple tools like magnifying glasses.